There are two bars that go across the soundboard that the strings are stretched over (one bar is called the bridge, the other is the nut).

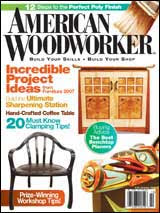

In the pictures here you can see the beginning of the bridge. So far it's sawn out to rough size and shape... now I need to shape it to the exact dimensions with a spoke shave.

The plans for the instrument provide measurements for four cross sections of the bridge, down to the 1/100th of an inch. This is a critical part of the instrument because errors in the dimensions could cause the strings to buzz, and it also affects the scale quality.

(In the picture, everything is upside down, but you can get an idea for where things go.)